![[list:title]](/template/feilihudoo2022/images/beerpic01.jpg)

![[list:title]](/template/feilihudoo2022/images/beerpic02.jpg)

![[list:title]](/template/feilihudoo2022/images/beerpic03.jpg)

![[list:title]](/template/feilihudoo2022/images/beerpic04.jpg)

Custom-made premium brewing systems and turn-key auxiliary equipment specifically designed to answer all the needs and requirements of the Brewing sector.

The automatic depalletizer is mainly suitable for the automatic depalletizing of the whole stack of empty cans, which can save a lot of labour and improve production capacity.

The overall design of filling and seaming machine is suitable for the filling and sealing of steam cans with high speed, smooth running and good sealing quality.

The spray tunnel beer pasteurizer, a newly developed product, integrates sterilization and cooling to achieve automatic, efficient, safe and sanitary sterilization for the filling line.

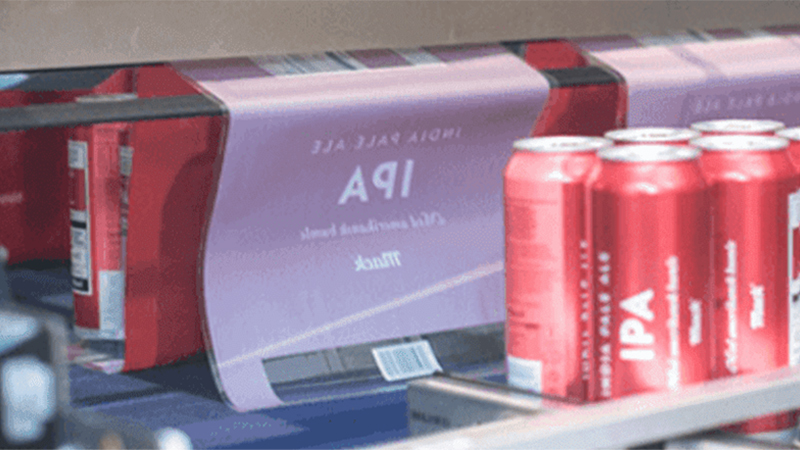

Post packaging machine with high automation, reliable control, simple operation is widely used in water, juice, carbonated drink, oil, wine, chemical, medical and other industries.

The conveyor system with a capacity of up to 48,000bph includes bottle warmer, bottle cooler, pasteurization spray tunnel, chain conveyor and case conveyor.

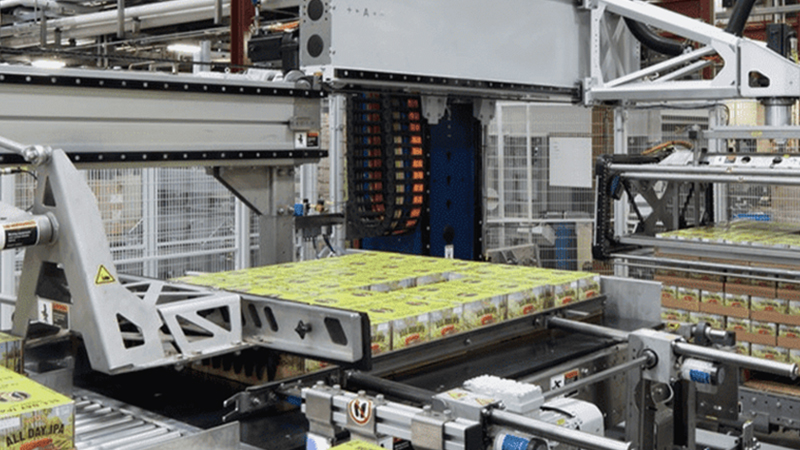

The automatic palletizer can put different products in a fixed order and stack them on the pallet automatically, which is easy to master and saves labour costs.

The cans visual inspection system has a good testing capacity and can detect cans’ appearance at high speed while the production line keeps running.

Phone